Products

Avionics & Interior

Avionic systems include communications, navigation, the display and management of multiple systems, and the hundreds of systems that are fitted to aircraft to perform individual functions.

We are experienced in producing parts for avionics and interiors as follows:

– Card Cages

– Chassis, Electrical Equipment

– Retainer

– Heatsink

– Seat Structure

– Refrigerator Pump, Shaft Cylinder

– Bezel

– Actuator

Engine Components

An aircraft engine is a component of the propulsion system for an aircraft that generates mechanical power.

We are experienced in producing parts for aircraft engines as follows:

– Piston, Housing

– Housing

– Beam

– Body

Brake & Landing Gear System

Braking and landing gear is the undercarriage of an aircraft or spacecraft and may be used for either takeoff or landing.

We are experienced in producing parts for braking and landing gear as follows:

– Insulator, Piston

– Bearing

– Plug, Retainer

– Level

– Piston

– Valve, Bleeder, Hydraulic

– Pin, Break Return

Aero Structure

An aerostructure is a component of an aircraft’s airframe. Include all or part of the fuselage, wings, or flight control surfaces.

We are experienced in producing parts for aero structure as follows:

– Intercostal, FWD Cargo Door Panel

– Shear Tie

– Hook

– Hinge Assy-Access Door

Capabilities

CNC Milling

Paradigm Aerospace is equipped with advanced 3 to 5 axis universal milling machines with high-precision and optimized speed meeting tight tolerances down to 0.005” and cutting part size up to 1 meter. We are experienced in handling a wide variety of material from Aluminum, Stainless Steel, Copper , Inconel to Titanium. With the aid of CADCAM software, we are able to achieve optimum cutting path, better quality and high accuracy.

CNC Turning

Paradigm Aerospace has 16 units CNC turning, auto lathe and turn mill machines with different capabilities in order to offer competitive solution to our customer. We coerce to produce CNC turning part of 5mm to 250mm in diameter with precision tolerances down to 0.0005”.

Sheet Metal Fabrication

The combination of fiber optic laser and turret press in a single machine increases our productivity, reduces costs, and eliminates many costly secondary operations. Programming time is saved, special tooling can be eliminated, set up time is less, and your custom parts can be finished in record time. And, we are able to cut up to 12 mm thick of material.

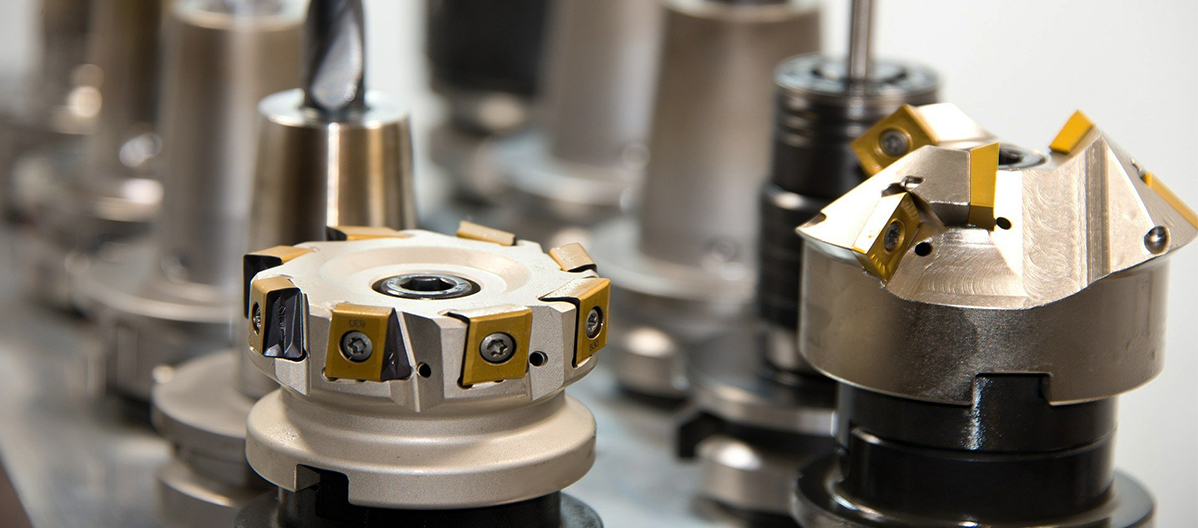

Tools Management

Conservation of the cutting edge is the cornerstone of a successful management program. We track and organize a fleet of cutting tools for turning and milling with numerical control machining tools created and stored under proper condition.